Main Frame Update:

Comparison of old and updated chassis (deflection wise) under 30000 Nm (22126.86 lbf*ft) torsional load (below). Previous deflection value in degree was 1.08 degrees, now it is 0.861 degree and there is no weight gain on the chassis a part from modification of the beams and some additional mini gussets on some weld points. Current calculated torsional stiffness is ~34480 Nm/degree, previous value was 27540Nm/degree (~20% stiffer chassis). Stress concentration on chassis beams and welds are also less.

Rear Frame 1st FEA Test Obtained Data:

Another FEA study for the rear frame which was done in Autodesk Inventor, Rear Frame is quite similar to Galmer GT rear frame (due to same power and gear train) with some differences and this one is symmetric. Torque range varies from 15000Nm to 80000Nm and torsional stiffness 79225.5221 Nm/degree which is mathematically achievable but failure occurs on some beams (eg. gearbox frame diagonal brace) beyond 50000Nm Torsional load. yet model is not perfect there are some residual stresses due to CAD design of the beam which the don't contact perfectly. calculation was done with 847676 elements (1635684 nodes). Detail of beams increases close to where torsional load was applied. Calculation to about 27 hours on incremental loads and computer crashed 5 times. otherwise calculation would have been less. Material used: 4130 Chrome-Molybdenum alloy steel which has a yield point at 460 MPa.

Comparison of old and updated chassis (deflection wise) under 30000 Nm (22126.86 lbf*ft) torsional load (below). Previous deflection value in degree was 1.08 degrees, now it is 0.861 degree and there is no weight gain on the chassis a part from modification of the beams and some additional mini gussets on some weld points. Current calculated torsional stiffness is ~34480 Nm/degree, previous value was 27540Nm/degree (~20% stiffer chassis). Stress concentration on chassis beams and welds are also less.

|

| Updated chassis from March 2015 (tested in May 2015) |

|

| Chassis from late 2014 |

Rear Frame 1st FEA Test Obtained Data:

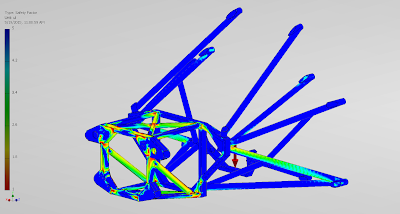

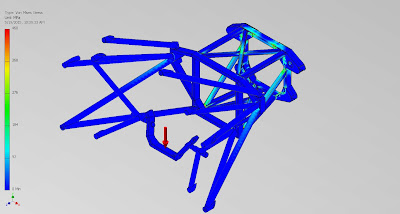

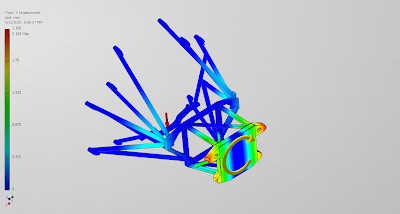

Another FEA study for the rear frame which was done in Autodesk Inventor, Rear Frame is quite similar to Galmer GT rear frame (due to same power and gear train) with some differences and this one is symmetric. Torque range varies from 15000Nm to 80000Nm and torsional stiffness 79225.5221 Nm/degree which is mathematically achievable but failure occurs on some beams (eg. gearbox frame diagonal brace) beyond 50000Nm Torsional load. yet model is not perfect there are some residual stresses due to CAD design of the beam which the don't contact perfectly. calculation was done with 847676 elements (1635684 nodes). Detail of beams increases close to where torsional load was applied. Calculation to about 27 hours on incremental loads and computer crashed 5 times. otherwise calculation would have been less. Material used: 4130 Chrome-Molybdenum alloy steel which has a yield point at 460 MPa.

|

| Safety factor map |

|

| Safety factor map |

|

| Von Mises stresses |

|

| Von Mises stresses |

|

| Resultant displacement |

| ||

| Displacement in Y direction |

No comments:

Post a Comment